SERVICES

Asset Integrity

With over 10 years of experience in the challenging Nigerian Oil & Gas Industry means we have both the know how and experience in areas such as business consulting operational readiness, and commissioning and maintenance integration.

Carmel’s Tekno partners with OEMs in order to meet your maintenance needs in the areas of inspections, surveys and repairs. We facilitate the prompt response of OEM expert so that we bear the risk, deliver quality services on time and our clients are satisfied.

Our extensive experience and commitment to operational excellence means our oil and gas customers can be confident that we will manage their assets safely and deliver their project on time and to budget.

Process Instrumenation Services No process/control system can perform correctly if it doesn’t get the correct information. We have been supplying, installing and calibrating Process Instrumentation for more than 8 years. With these years of experience, we are well positioned to assist with your current or future design, integration, operational or maintenance needs.

Whatever your system requirements; large or small, simple or complex, local or international; Carmel’s has demonstrated the ability to provide the solutions that will exceed your expectations; on time and within budget.

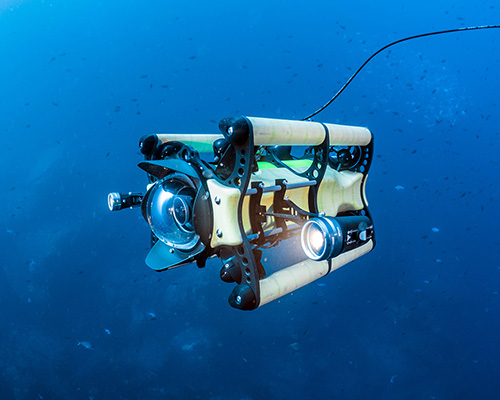

Subsea Asset Integrity Services

- Inspection, Maintenance, Monitoring and Repair

- Geographic Information Systems (GIS)

- Anamoly and Non-Conformance Management and Remediation

- Integrity Management and Engineering Analyses

- Facility Data Management (Digital Asset Based)

- Life-Cycle Information (LCI) Databases

- Virtual Reality Modeling - Inspection and Maintenance Planning, Asset Visualisation

Cathodic Protection Solutions

- Cathodic Protection to Pipelines and buried structures

- Cathodic Protection to Offshore Marine Structures

- Cathodic Protection to Offshore Structures

- Thick and Thin Film Coating Systems

- Factory Applied and Field Wrap Systems for Pipelines

Field Inspection

- NDT Services (UT measurement and scanning, Dye Penetrant Testing, MPI)

- Third Party Inspection (Survey, Construction, Coatings)

- Atmospheric Corrosion inspection

- Leak Detection

Pipeline Damage Repair Services

- Anti-Corrosion Protection of pipeline and Structures

- Reinforcement of On/Offshore Pipeline & Marine Structures

- Coating Inspection/Repair/Removal/ Reapplication

Cleaning and Inspection Solution

- Pipeline: Chemical cleaning by pumping of the chemical with a chemical safe pump, circulation, pickling and passivation etc.

- Exchangers/Vessels: Cleaning, preparatory and intrusive inspection services on process vessel and exchangers.